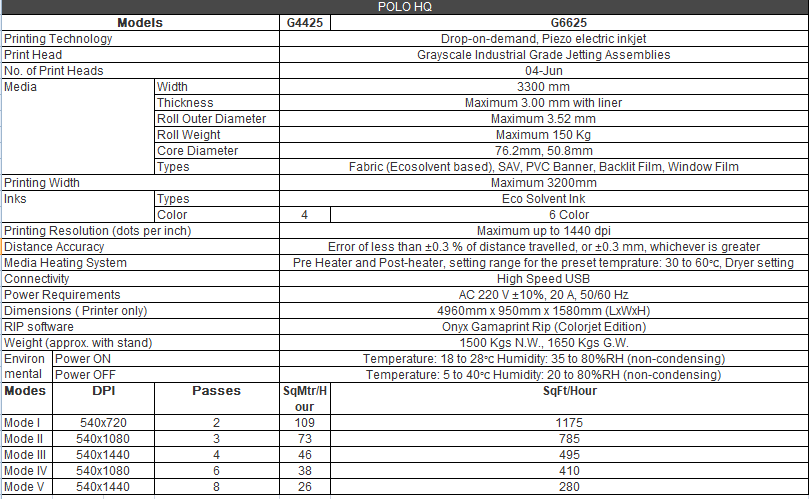

POLO HQ, the high-speed Industrial grade eco-solvent printer is built for speed & quality. At a speed of 93 sqm/hr. POLO HQ displays quality print for mass production supported by IR based effective evaporative drying system to meet the high volume requirement. The 3.2 mtr roll-to-roll eco-solvent printer based on industrial grade jetting assembly ensures accuracy at high speed. The environment-friendly POLO HQ is built on heavy duty structure made with high mechanical precision standard to meet the growing requirement of those who want speed with quality.

Polo HQ is highly eco-friendly and is based on Colorjet's GreenTech. GreenTech was born out of Colorjet's commitment to printing solutions in the eco friendly green printing domain. GreenTech is powered by Colorjet's unique GreenTech printing technology that enables printing with environment friendly eco solvent inks. GreenTech ensures low chemical emissions to reduce environmental and health hazards. GreenTech eliminates harmful cyclohaexanone and uses non volatile organic compounds(NVOCs) for print results that are water resistant, fade resistant, media independent and UV safe in addition to being more environment friendly. GreenTech works towards complete solutions that adequately successfully address human, environment, and commercial issue.