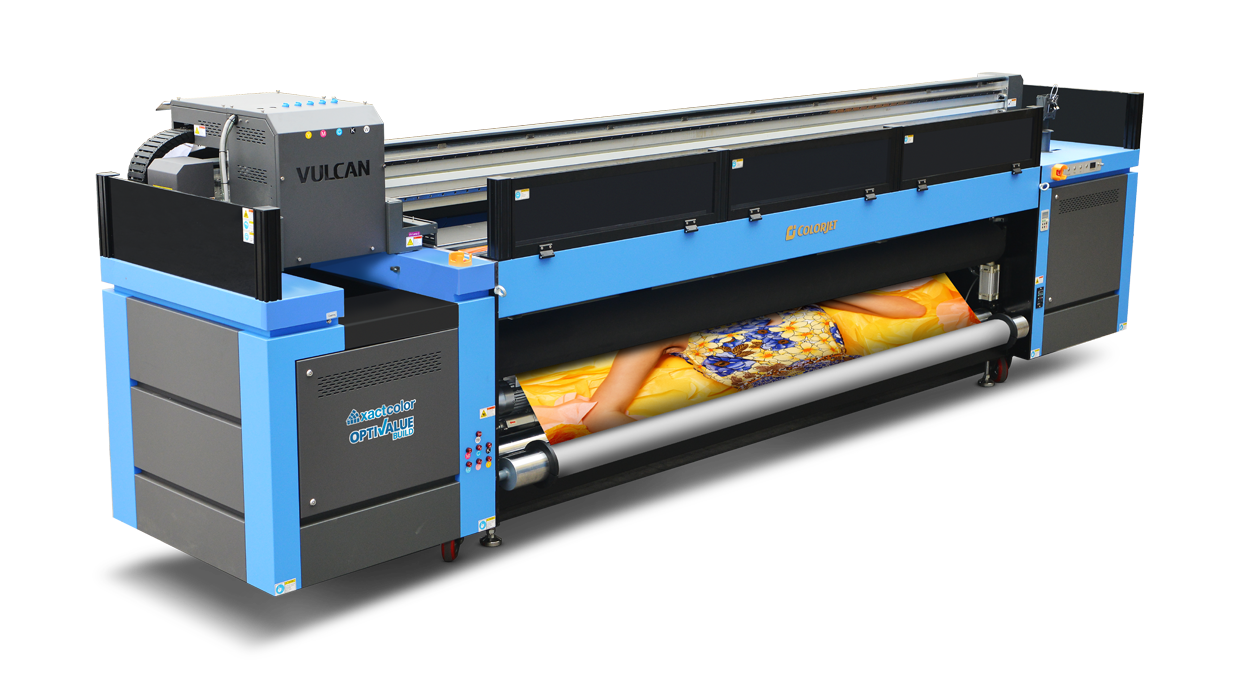

It’s time to print smarter and change the game of UV printing with ColorJet’s VULCAN, a high speed 3.2 m roll-to-roll UV LED Inkjet printer. Experience unprecedented print speed, high-quality, and lucrative total cost of ownership with our UV roll to roll printer VULCAN. It offers a variety of applications to help your print business grow with its versatile media handling capabilities that support a variety of flexible media, like backlit fabric, ceiling film, vinyl, advertising banner, PET, wallpaper, etc. It is an industrial UV printing machine that has a robust beam with high precision mechanical accuracy. This ensures high quality back to back printing with accurate dot placement solution and low ink consumption making VULCAN, a perfect solution for indoor and outdoor applications. Embedded with the UV LED curing process, it has several benefits that make printing more economical and ecological. Its smartly integrated design is convenient for trouble-free operation.

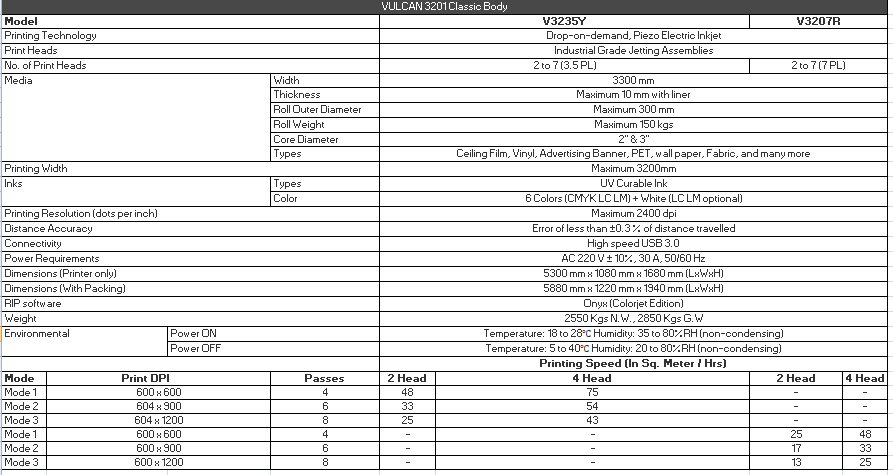

Built on a robust industrial production platform and never seen before automation, this industrial UV printing machine is capable of printing high volumes and withstands heavy-duty cycles without compromising on the quality. VULCAN is powered by a V8 processor that delivers unmatched printing quality at a lightning-fast speed of up to 678 sq. feet per hour. This industrial UV printing machine is equipped with a highly interactive and user-friendly interface. Its advanced feeder technology with pneumatic controlled rubber rollers ensures proper media feeding and maintains proper tension of media. ColorJet’s variable drop technology with a minimum drop size of 3.5 Pico liters ensures smooth and quality printing by correct placement of each ink drop on the media. ColorJet’s intelligent pass optimization specially designed to prevent banding and the three-layer printing enhances the quality of graphic design for the same day and night effect in backlit signage. The integrated eco cooling system maintains print substrate temperature and prevents media distortion. This back to back printing machine comes equipped with carriage safety sensors, which helps to protect the print heads from the accidental crash with a print substrate

Embedded with UV LED lamps for the curing process and has several benefits which makes printing more economical and ecological:

In multi-layer technology, print heads are arranged in staggered or inline format. This means that the multi-layer technology offers unbeatable quality by mixing appropriate portion of white with other color to enhance the visibility of the print. This can be proved best for the backlit print application. The multi-layer technology offers the following printing modes of white color: