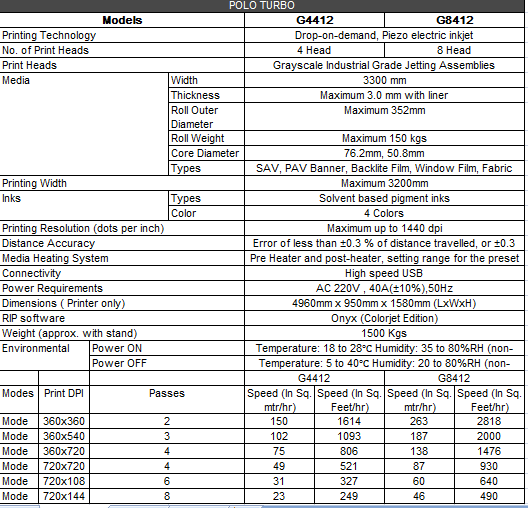

POLO TURBO, the high speed industrial grade solvent printer is built on a heavy-duty structure. The independent drive technology is renowned for its high speed, high quality output and reliability, as well as low running cost. In POLO TURBO solvent printer the independent drive technology drives each nozzle independently to achieve high speed production up-to 1600 sqft./hr. POLO TURBO is supported by IR-based effective evaporative drying system, to meet high-volume requirements. This solvent printer has 3.2 meter roll-to-roll capability and is based on an industrial-grade jetting assembly which ensures accuracy at high speed. This is the best solution for diverse indoor/outdoor applications.